方案與應用/環境獵能應用

光能

光伏能方案

您需要光能(太陽能)發電的方案嗎?

假設您的物聯網無線裝置使用來自太陽光、燈泡、燈管等光能來為電池充電,您就可能會需要三天兩頭更換電池,因為他們很快就沒電啦!真是營運成本的硬傷!

說實話,光從您裝置的週邊可能就已經有足夠的環境能源能提供您所需的能源。

依照光照條件的不同(可能是陰暗的室內角落,亦或是晴朗無雲的戶外場景),傳統的太陽能板(PV Cells)每平分公分的面積可產出10微瓦(10µW)至10毫瓦(10mW)的能量。

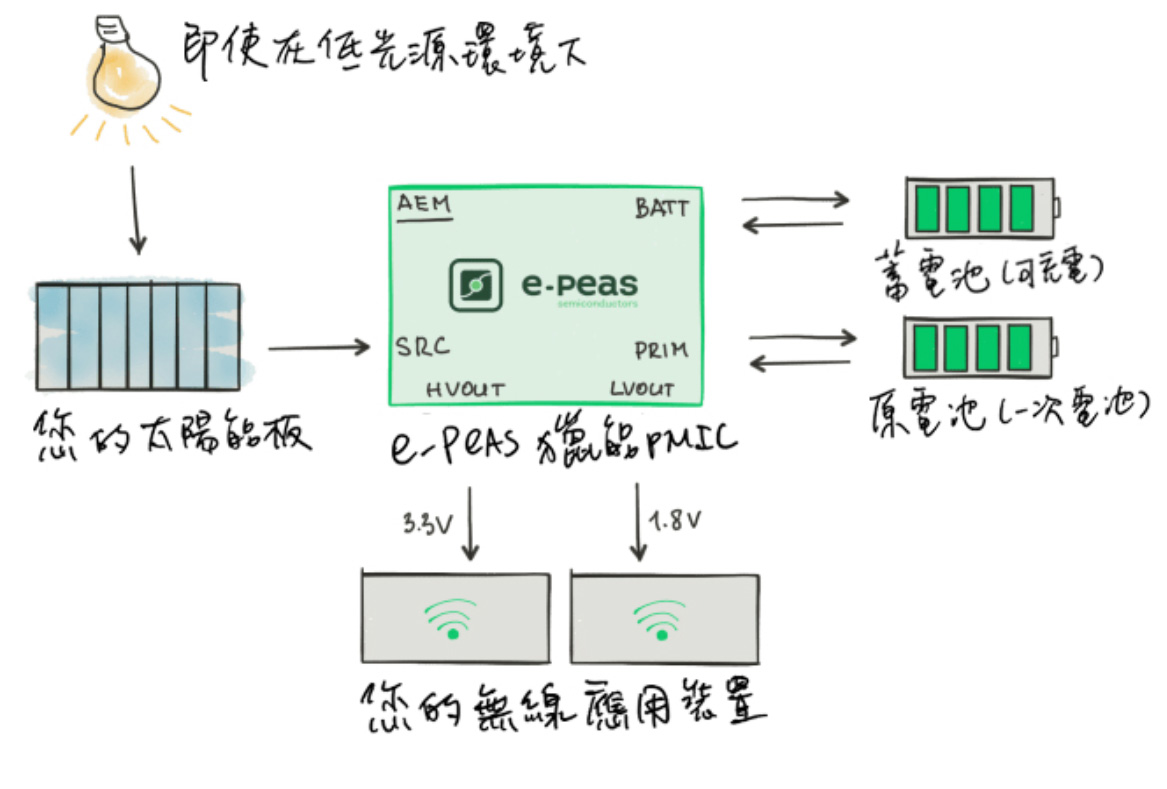

使用適當的材料與呎寸條件下,您的太陽能板將可與e-peas領先的獵能電源管理模組(PMICs )結合應用,可利用環境光源來為您的IoT設備充電,省下可觀的電池維護/替換成本。

E-peas提供了什麼樣的產品?

一個可以讓您設備上的電池「長生不老」的解決方案!E-peas創新的IC可自動、有效率地在任何光源環境下幫您的電池充電,即便是搭配3微瓦(3µW)的太陽能板也能充電!

E-peas目前已提供兩種光能方案:

- AEM10940 可支援兩片產出 11µW 至 32.5mW 不等的太陽能板

- AEM10941 可支援七片產出 3µW 至 625mW 不等的太陽能板

E-peas如何與競爭對手相比與眾不同?

E-peas獨門的AEM架構有以下特點:

- 高能源轉換效率

- 最快速的超級電容器(the fastest supercapacitor charge)

- 冷啟動功率最低(the lowest cold-start power)

- 電路面積要求最小,外部零件要求最少(the smallest footprint and associated components BOM)

此外,浩陽與e-peas工程師也會提供直接的技術支援服務!

產品選擇

我們推薦在光伏能(太陽能)發電方案中使用以下產品:

| 料號 | Vin | Cold-start | Pin | Pout | MPPT | 包裝 |

| AEM10941 | 50mV to 5V | 380mV | 1μW to 625mW | 10mA@1.8V | Yes | QFN28 5x5mm |

應用案例

智慧灌溉

有別於傳統農家使用的灌溉系統仰賴於定點定時的灑水系統,智慧灌溉的理念是利用模組感測器實時監控氣候、土壤狀況、溫濕度來動態調整灑水的時間與水量。

舉例來說,戶外的氣溫上升、降雨量下降,智慧灌溉系統皆可以因地制宜,依照場地的土壤種類或品質,灑水器的大小與規格等做相對應的調整。加上智慧感測器後,現場感測深度土壤水分連續變化情況、地表及地下土壤溫度、作物活躍吸水根部位置及分佈情況、氣象數據等諸多對生長環境產生影響的因素。智慧互聯的物聯網灌溉系統更可連結生態大數據,提供本地歷史與未來的天氣預測數據、未來的降雨預測數據、農作物耗水規律數據、土壤水文特徵數據等。基於現場感測和本地的生態大數據的無縫融合,根據作物生長訊息,自動分析根系活躍吸水位置及分佈比例;智慧識別作物缺水危險性、田間持水量、飽和含水量;智慧計算土壤有效儲水量、土壤蓄水潛力、土壤水滲透速率等,並預測未來的降雨量、作物需水量等訊息作綜合計算,才可以科學動態地做出一次灌溉延續時間、灌溉量、灌溉周期等決策。

東亞地區由於獨特的地形影響,季風亞洲帶夏冬兩季降雨量變換的巨量差距以及季風含水量不穩定性連帶著對本地區的農業生產有著至關重要的影響。此時更需要智慧灌溉系統來守護作物的生長,確保產量最大化。

E-peas的應用方案

E-peas的電源管理方案可搭配太陽能生電方案,藉由自然中的太陽光來或取能量,供智慧灌溉所需要的器材設備使用。有關更詳細的e-peas應用,請見下方「AEM10941的光伏能應用」。

智慧放牧:牲畜定位追蹤

隨著各國政府及消費者對於動物保護權益及食物鏈健康意識不斷高漲,有機動物產品產品的需求不斷升高。或甚有以政策法令手段要求農蓄業者善待動物、不許栓綁,提供動物能隨時自由到戶外活動的新型態蓄牧經營模式正大舉改寫農業生態。但要能悉心照料每一頭牲畜以達到法規與消費者期待,若沿用傳統人力密集的方式恐不敷成本。這也是智慧放牧應運而生的遠因。

透過繫在每一頭牲畜上的感測器,現在農場主人可以放心地讓牛羊在風吹草地的原野中自由活動。感測器除了最基本的監控牲畜的位置,更可做其他額外的應用,包括牲畜的健康狀況等,即時回報。

以中國塞北為例,過去牧民們依靠傳承數千年口耳相傳的經驗在草原中放牧。隨著時代更迭,都市化的發展,更多牧民們不再過著逐水草而居的游牧生活,而是爲了保護草原生態、改善生活條件,搬到距離牧場較遠、條件較好的城鎮定居。然而,爲了管理牧場上飼養的牛、駱駝等牲畜,牧民不得不遠距離奔波。

若使用了智慧放牧,牧民們則而不用勞苦奔波地時時往返草原。只要在家中即可輕易地在家中遠距實時監控,待必要時在前往現場排除狀況。運用了智慧放牧的牧民們不用再雇人放牧了,每個月省下的時間與金錢開支更可運用於做後續奶制食品等終端產品,提高生產力。

E-peas的應用方案

E-peas的電源管理方案可搭配太陽能生電方案,藉由自然中的太陽光來或取能量,供智慧放牧的牲畜定位系統等物聯網(IoT)裝置所使用。自環境生電的優勢更在於不用更換電池,除了減少污染,更可以避免裝置電源耗盡而無法工作的窘境。目前成功的案例包括位於澳洲的牛隻定位系統,已成功地利用E-peas的太陽能方案為牛耳標上的衛星追蹤器永續定位。有關更詳細的e-peas應用,請見下方「AEM10941的光伏能應用」。

魚塭水質監控

傳統養殖漁業的運作,不但費力耗時,更是高風險產業。面臨風災、水災,病毒性疾病,或是增加水中溶氧量的水車設備偶發故障等,都讓養殖戶付出的心力與資金一夕之間化為烏有。因此,養殖戶習慣把自己的時間投入在照看魚塭,不敢出門遠行,以免突發狀況時趕不及搶救。

「養魚要先養水」,水質穩定,才能養好一池魚。導入智慧水質監測系統後,養殖戶更能掌握魚塭水質變化、魚隻健康狀況,並進一步降低魚的死亡率、減少用藥,以及提高育成率與獲利率。養殖戶更不必整天被綁在魚塭看水顧魚,而有更多空閒的時間,顧好家庭與生活品質、進修增進養殖技術或開拓銷售通路。

E-peas的應用方案

透過E-peas的電源管理方案可搭配「太陽能」或「冷熱溫差」生電方案,藉由自然中的太陽光來或取能量,供水質監測所需要的器材設備使用。有關太陽能更詳細的 e-peas應用,請見下方「AEM10941的光伏能應用」。部份客戶亦選擇了「冷熱溫差」的生電方式來提供水質監測器的永續電力。基於水中溫度低於水表面因日照所承載的相對高溫,水上、水下的溫差即是很好的發電來源,可提供間測模組源源不絕的能量來源。有關冷熱溫差的應用,請見此頁。

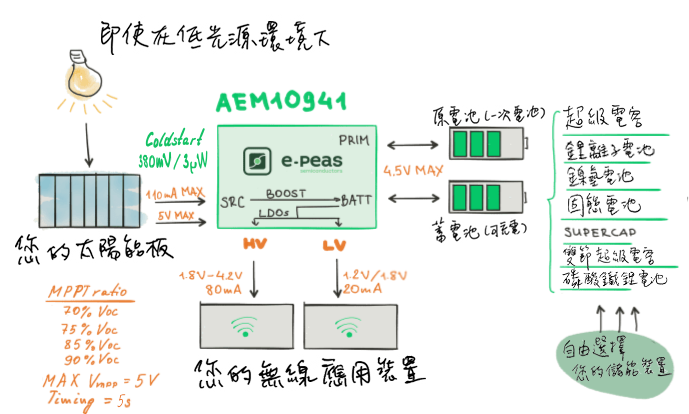

AEM10941 的光伏能應用

E-peas之光伏能能源採集IC方案 – AEM10941 – 是新一代能源採集子系統。可對接由多至七片得的太陽能板取得能源,並同時儲存能量至可回充的儲能裝置,並提供系統兩套獨立的調節電壓。這套方案可以讓產品設計師與工程師延長電池的壽命,甚至永久地移除一次性電池的配置,可在多種無線裝置上應用,例如工業監控、自動智慧家居與穿戴式裝置等。

AEM10941可接收的電流可高達125 mA。結合了超低功耗的升壓變換器(boost converter)可對 鋰離子電池(Li-Ion battery)、薄膜電池(thin film battery)或是傳統或超級電容等儲能裝置充電。這個升壓變換器可以接收的電壓範圍由50 mV 至 5V。透過特殊的冷啟動線圈,在儲能裝置尚無電力的情況下可以接收低至 380 mV的電壓以及 3 µW的功率。

一般而言,我們系統所提供的1.8V的低電壓已足夠驅動微控制器(microcontroller)。另一組高電壓輸出則可讓客戶設定,用於驅動無線電收發器等應用。兩路系統輸出皆搭配了高效能的低壓差穩壓器(LDO)以確保低噪度與高穩定性。

透過調整腳位可以啟用IC內部預設的不同配置以搭配您不同儲能裝置的應用。同時亦可以在高電壓輸出的通道上選擇不同的電壓。若搭配電阻則可以搭配出更多種應用模式。

我們的IC集成了一般無線感測器所需的主動元件,讓您在電路設計上至多只需要七個外部元件,以減少電路板總面積與系統成本,加速產品上市時間。

超低啟動電壓功耗

- 380 mV 輸入電壓與 3 µW 輸入功耗即可冷啟動系統(cold start)

超低功耗升壓調節器(Boost regulator)

- 開放性電路每 5 秒偵測一次 MPPT

- 透過兩個腳位設置MPPT

- Voc 比例可定義為70、75、85 或 90%

- 輸入電壓可工作範圍由 50 mV 至 5V 之間

- MPPT 電壓可工作範圍由 50 mV 至 5V 之間

整合的低電壓低壓差穩壓器

- 1.8 V 高效能

- 負載電流最高至 10 mA

- 可由外部控制電源閘控

整合的高電壓低壓差穩壓器

- 可在 2.2 V to 4.2 V 之間配置

- 負載電流最高可至 80 mA、 300 mV 壓差

- 可由外部控制電源閘控

多種儲能裝置選擇

- 可用程式化控制壁免過度充電(overcharge)及放電(overdischarge)

- 可搭配各種可充式電池或(超級)電容

- 快速的超級電容充電應用

- 電池用竭前的餘量警示

- 穩壓器開啟時的動作警示

最小化的電路板面積與系統成本

- 只需要七個被動元件搭配

額外的選配原電池方案

- 用戶亦可搭配原(一次性)電池,在可充式儲電裝置沒電時可作備用電源

文檔

| 項目 | 版本 | 最後更新日 | 下載 |

| AEM10941 product brief | PB_AEM10941_REV1.3 | 17/05/2018 | Download |

| AEM10941 datasheet | DS_AEM10941_REV1.3 | 25/09/2018 | Download |

| AEM10941 user guide (for evaluation board) | UG_AEM10941_REV1.0 | 25/09/2018 | Download |

| AEM10941 mini board | MB_AEM10941_REV1.2 | 08/04/2019 | Download |

| AEM10941 mini evaluation board | MEB_AEM10941_REV1.0 | 19/03/2019 | Download |

| AEM10941 extDCDC mini evaluation board | MEB_AEM10941_extDCDC_REV1.0 | 19/03/2019 | Download |